Measurement-Technik Complete wheels

TUG

Uniformity measurement in production lines is a difficult subject regarding compactness, robustness, cycle time and reliability. inmess is a leading provider of Tire uniformity measurement machines

Uniformity measurement in production lines is a difficult subject regarding compactness, robustness, cycle time and reliability. inmess is a leading provider of Tire uniformity measurement machines

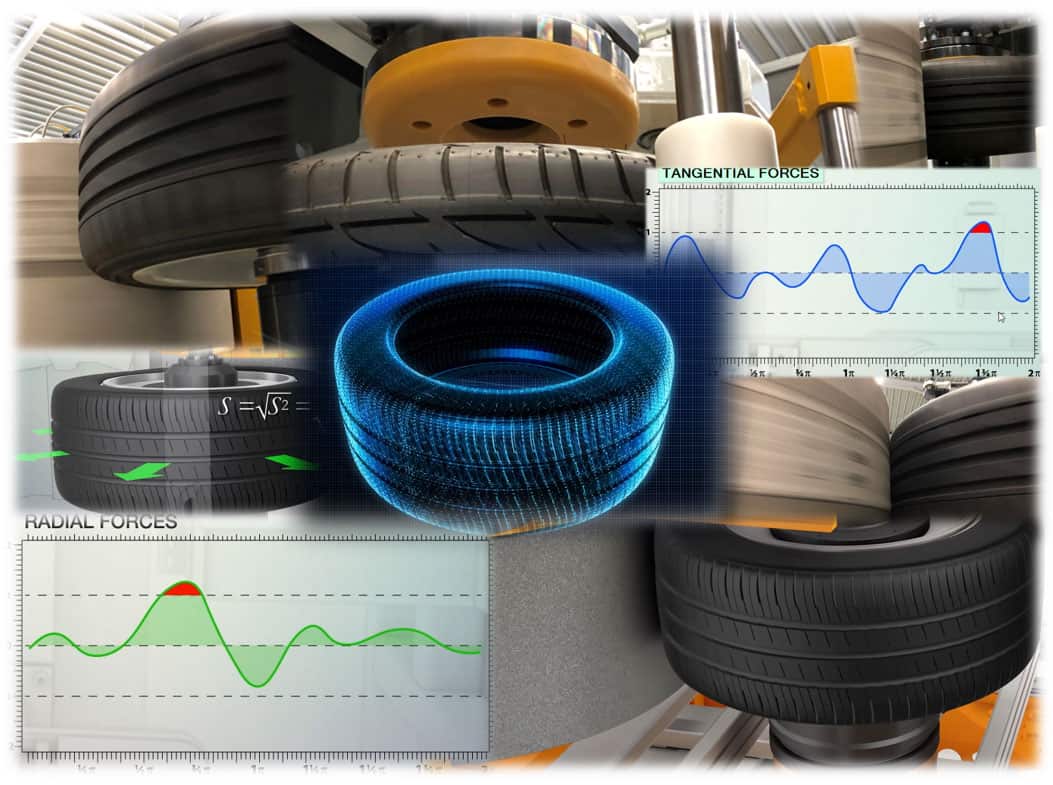

Tire Uniformity Grading Machine (TUG)

The tire uniformity measuring machine is used to measure the tire uniformity for complete vehicle wheels and determines the radial and lateral force fluctuations of the rolling wheel, optionally its ply steer and cone effect, as well as the radial and lateral runout and customer-specific calculations such as TUZ for example.

The machine is optionally available with a DOT detection system as well as a geometry measuring system

inmess GmbH . Europaallee 7

28309 Bremen/Germany

Fax +49(0)-421-489909-25

inmess GmbH . Europaallee 7 . 28309 Bremen/Germany

T +49(0)-421-489909-0 . Fax +49(0)-421-489909-25 . sales@inmess.de

inmess GmbH . Europaallee 7

28309 Bremen/Germany

Fax +49(0)-421-489909-25

Copyright by inmess GmbH 2020 | Legal Info | Privacy Policy